China Gold Supplier for Backlighting Led - Direct LED backlight – Shineon

China Gold Supplier for Backlighting Led - Direct LED backlight – Shineon Detail:

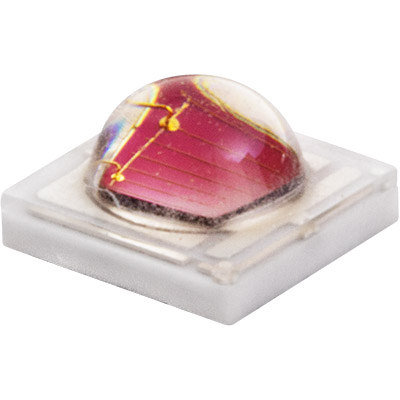

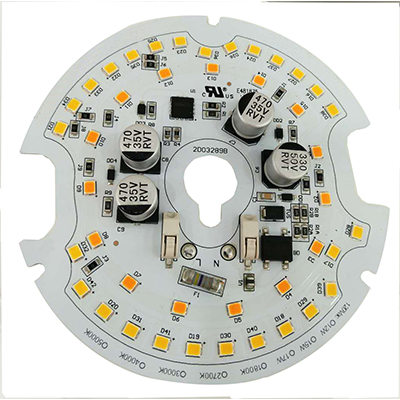

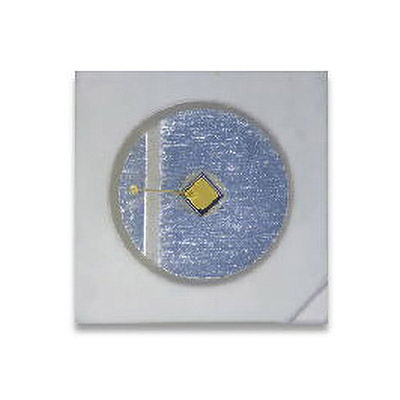

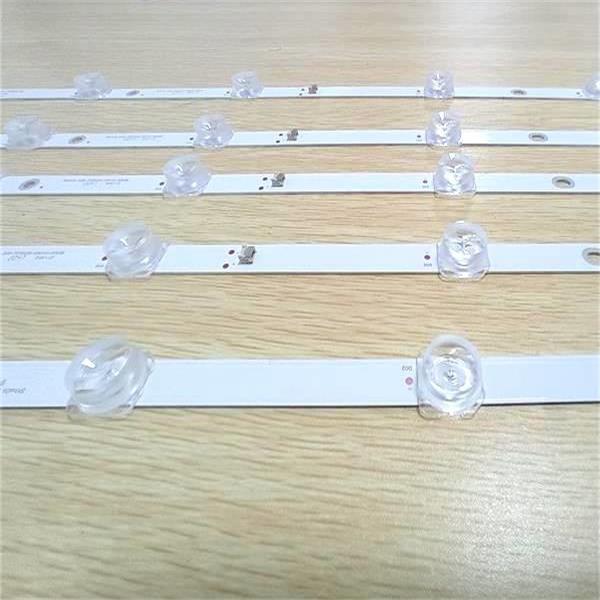

When edge-lit LED backlights are used in medium and large-sized LCDs, the weight and cost of the light guide plate will increase with the increase in size, and the brightness and uniformity of the light emission are not ideal. The light panel cannot realize the regional dynamic control of the LCD TV, but can only realize simple one-dimensional dimming, while the direct-lit LED backlight performs better and can realize the regional dynamic control of the LCD TV. The direct backlight process is relatively simple and does not require a light guide plate. The light source (LED chip array) and PCB are placed at the bottom of the backlight. After the light is emitted from the LED, it passes through the reflector at the bottom, and then passes through the diffuser on the surface to increase brightness. The film is ejected evenly. The thickness of the backlight is mainly determined by the height of the cavity between the reflective film and the diffuser. In theory, on the premise of meeting the installation requirements and luminous brightness, the greater the cavity height, the better the uniformity of light emitted from the diffuser.

Download as PDF

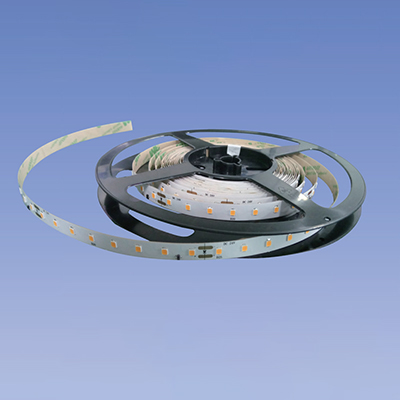

Direct LED backlight

Product detail pictures:

Related Product Guide:

We know that we only thrive if we can easily guarantee our combined cost competiveness and high-quality advantageous at the same time for China Gold Supplier for Backlighting Led - Direct LED backlight – Shineon , The product will supply to all over the world, such as: Korea, United States, USA, Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. We hope to cooperate with more customers for mutual development and benefits. We welcome potential buyers to contact us.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!